In the manufacturing and plastics industry, efficiency and precision are critical for success. One of the technologies that has revolutionized production is the 4 Station Mould – also commonly spelled as 4 Station Mold in American English. These advanced systems have become indispensable for companies producing plastic components, rubber parts, and similar molded products at high volume while maintaining exceptional quality.

What is a 4 Station Mould / 4 Station Mold?

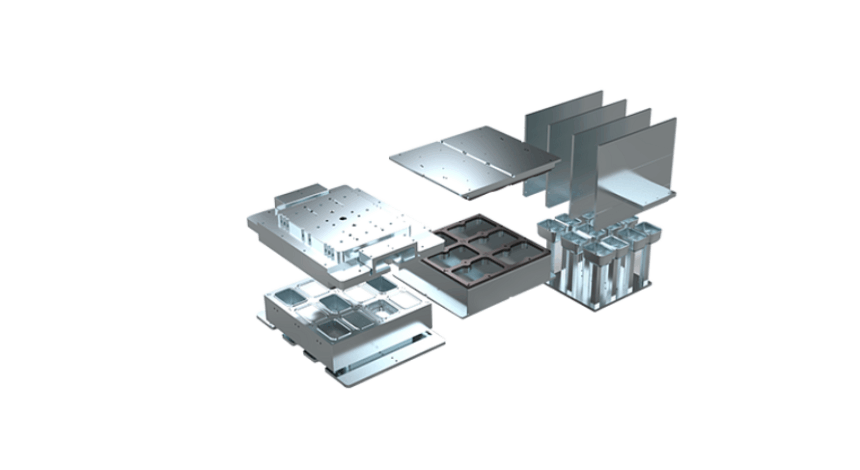

A 4 Station Mould or 4 Station Mold refers to a molding system that features four separate stations working in a coordinated cycle. Typically used in processes like injection molding, compression molding, or rotational molding, this system allows for multiple steps to occur simultaneously.

For example, while one station injects material into the mold, another can be cooling the product, a third might be unloading finished parts, and the fourth can be prepping for the next cycle. This continuous rotation dramatically reduces downtime and increases output – making it ideal for industries that demand speed and precision.

Key Benefits of Using a 4 Station Mould / 4 Station Mold

-

Increased Production Efficiency

The primary reason manufacturers invest in a 4 Station Mould is productivity. Since multiple operations take place at once, cycle times are shortened. Instead of waiting for one stage to finish before starting the next, the mold rotates through stations seamlessly. -

Cost Savings

A 4 Station Mold helps lower labor and operational costs. With fewer pauses in production, energy consumption is optimized, and fewer machines may be needed to achieve the same output. -

Improved Quality and Consistency

These systems ensure that every part is processed under the same conditions, leading to uniform results. This is especially important in industries like automotive, medical, or consumer goods where quality cannot be compromised. -

Versatility for Various Materials

Whether you are working with thermoplastics, rubber, or composite materials, a 4 Station Mould can be adapted to handle different materials and product designs.

Applications of 4 Station Mould / 4 Station Mold

The 4 Station Mould is used in a wide range of industries:

-

Automotive Components: Interior panels, gaskets, and under-the-hood parts can be produced faster with a 4 station setup.

-

Footwear Industry: Many shoe soles and rubber footwear components are made using 4 Station Molds for high efficiency.

-

Medical Products: Syringe components, seals, and other medical-grade items benefit from the precise, consistent output of multi-station molding.

-

Consumer Goods: Everyday plastic items like containers, kitchen tools, or toy components are often made using this technology.

4 Station Mould vs. Traditional Single-Station Mold

While single-station molds serve their purpose for smaller batches, the difference in efficiency is significant. A single-station mold can only perform one task at a time – fill, cool, or eject – whereas a 4 Station Mould performs all these tasks simultaneously across different stations.

The result? Manufacturers can multiply production speed without multiplying labor or space requirements.

Why Choose a 4 Station Mould / 4 Station Mold for Your Business?

If your production requires high volume, consistent quality, and fast turnaround, upgrading to a 4 Station Mold might be the smartest move. Many companies see a return on investment quickly because the increase in productivity offsets the initial equipment cost.

Additionally, the flexibility of this system means you can produce different product lines on the same machine with minimal downtime for mold changes – a crucial factor in today’s fast-moving markets.

The 4 Station Mould (or 4 Station Mold) is more than just an industrial tool – it’s a productivity powerhouse. By allowing four stages of the molding process to run at once, it maximizes efficiency, reduces costs, and delivers consistent, high-quality results.

Whether you are in automotive, footwear, medical, or consumer goods manufacturing, investing in a 4 Station Mold can give your business the competitive edge it needs. As global demand for high-quality molded products grows, adopting advanced systems like the 4 Station Mould is not just an option – it’s a necessity for staying ahead in the industry.