In today’s fast-paced world of industrial manufacturing, nail making machines are the unsung heroes. From tiny brads for furniture to heavy-duty construction nails, these machines ensure speed, consistency, and reliability. But how exactly do they work? And why has the demand for a robust nail production machine never been higher?

Let’s dig into the world of nail making machines, explore how they function, what types are out there, and how they tie into related equipment like thread rollers.

Nail production machine – The heart of mass nail manufacturing

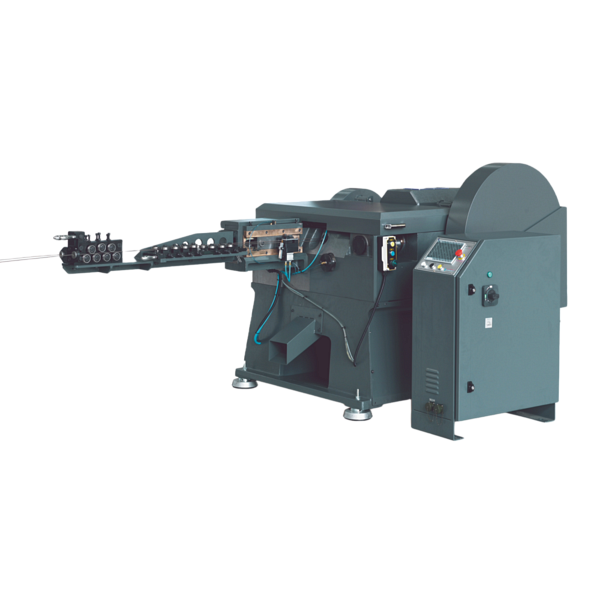

A nail production machine is designed to automate the creation of metal nails from raw wire. The process typically involves cutting, heading, and shaping metal wire into consistent, usable nails. These machines can churn out thousands of nails per minute, depending on the model.

So what makes a nail production machine so essential?

-

Speed and volume – Modern machines produce nails in bulk, far outpacing manual methods or older systems.

-

Precision – With minimal tolerance for error, these machines ensure each nail is cut to size and finished perfectly.

-

Adaptability – Most machines can be adjusted to produce different nail sizes and types with minimal downtime.

At their core, they use a feeder system to draw in wire, which is then cut, headed, and shaped. The cutting dies and punches can be swapped out depending on nail size or material, making these machines highly versatile.

Wondering what types of nails can be made using a nail production machine? The answer might surprise you.

-

Common nails

-

Roofing nails

-

Coil nails

-

Concrete nails

-

Finish nails

-

Brad nails

That’s a lot of variety for one type of machine, right?

Nail making machines – Types, features, and operation

When diving into the world of nail making machines, it’s clear that not all are created equal. Different machines are tailored for different use cases, materials, and production needs. Let’s break it down.

1. Automatic nail making machines

These are the most common type. Fully automated, they can feed wire, cut it, shape it, and even polish nails without human intervention.

2. High-speed nail making machines

Built for industrial-scale production, these models can output up to 1000 nails per minute. They also tend to offer better energy efficiency and stability.

3. Low-noise and energy-efficient machines

With stricter environmental standards, manufacturers are moving towards quieter, more energy-efficient options that reduce vibrations and require less power.

4. Special-purpose machines

These include custom machines for producing nails of odd shapes or for working with non-standard metals.

Key features to look for:

-

Easy die changeover system

-

Automatic lubrication

-

PLC control panel

-

Safety enclosures and sensors

-

Minimal material waste design

Whether you’re starting a small nail production line or scaling to factory-grade levels, choosing the right nail making machines will determine your operational efficiency.

Nail manufacturing machine – How it fits into the production line

A nail manufacturing machine is just one piece of the puzzle. Modern nail factories include a full chain of machines that handle wire drawing, nail making, shaping, and finishing.

Here’s what a typical production line might look like:

-

Wire drawing machine – Reduces steel wire to the desired diameter.

-

Nail manufacturing machine – Cuts and forms the nails.

-

Polishing drum – Cleans the nails for a smooth finish.

-

Thread rollers – For nails that require threads (like drywall or screw nails).

-

Packaging unit – Final step before shipping.

The nail manufacturing machine is where the wire gets transformed into a product ready for the market. It’s here that the size, head type, and shank design are decided.

But what if your nails need threads?

Thread rollers – Adding grip to your nails

Not all nails are smooth. Some require added grip to stay in place, especially for drywall or construction applications. That’s where thread rollers come in.

Thread rollers are machines that use high-pressure dies to roll spiral threads onto the shank of a nail. Unlike cutting, this method preserves the integrity of the metal and offers stronger, more precise threading.

Benefits of using thread rollers:

-

Higher tensile strength

-

No metal waste (unlike cutting)

-

Improved grip and holding power

-

Faster production time

These machines can be used in tandem with nail making machines or as a post-processing step. Modern facilities often include automated feeders between the nail production and threading stages to maximize throughput.

So, is threading always necessary? Not quite. But in high-demand industries like construction or furniture assembly, threaded nails offer a performance edge that’s hard to beat.

Frequently asked questions

How much does a nail production machine cost?

It depends on capacity, features, and brand. Entry-level machines can start around $5,000, while industrial-grade units may exceed $50,000.

Can one machine make different types of nails?

Yes. Most nail making machines allow for easy tooling changes, so you can switch between sizes and head types without buying a new machine.

What materials can be used?

Mostly low-carbon steel, but some machines can process copper, brass, or aluminum, depending on their build.

Do I need separate machines for threading?

Only if you need nails with threads. In that case, investing in thread rollers will be necessary for optimal results.

The future of nail production is here

The nail industry may seem simple at first glance, but the technology behind it tells a different story. Modern nail making machines, supported by thread rollers and other advanced tools, are enabling manufacturers to reach new levels of efficiency, customization, and quality.

Whether you’re launching a new workshop or upgrading an existing factory, investing in the right nail production machine or nail manufacturing machine is key. The machines you choose will shape not just the nails you produce, but the strength and success of your entire business.

Curious to learn more about nail machines, automation trends, or how nail making machines can boost your production output?

Explore our full range of solutions here: https://www.zeus-techno.com and find the perfect machine for your operation.